Understanding the Thermoforming Manufacturing Process

By: Nick Curry, Social Media Manager

In today’s fast-paced manufacturing world, efficiency and flexibility are crucial. Thermoforming has emerged as one of the most widely used plastic forming processes because it offers both. From everyday packaging to durable automotive parts, thermoforming provides an adaptable and cost-effective solution for shaping plastic materials into functional products.

What Is Thermoforming?

Thermoforming is a manufacturing process that involves heating a plastic sheet until it becomes pliable, then forming it over a mold to achieve the desired shape. Once the plastic cools and hardens, it is trimmed and finished into a usable part. This method is popular across industries because it can produce lightweight, strong, and cost-efficient components in a wide range of sizes.

The Thermoforming Process Step by Step

-

Heating the Plastic Sheet

The process begins with a flat sheet of thermoplastic material, such as ABS, polystyrene, PET, or polycarbonate. The sheet is heated in an oven until it reaches a pliable forming temperature, typically between 250°F and 400°F, depending on the material. -

Forming the Sheet

Once softened, the plastic is stretched over or into a mold. Two common forming techniques are used:-

Vacuum Forming: A vacuum pulls the heated sheet tightly against the mold.

-

Pressure Forming: Pressurized air pushes the sheet onto the mold for greater detail and precision.

-

-

Cooling and Setting

After forming, the plastic is allowed to cool, either naturally or with the help of fans and chillers. As it cools, the material hardens and retains the shape of the mold. -

Trimming and Finishing

Excess material is trimmed away, and secondary operations such as drilling, painting, or assembly may be performed. The leftover plastic can often be recycled and reused, adding to the process’s efficiency.

Advantages of Thermoforming

Thermoforming offers several benefits that make it a go-to manufacturing method:

-

Cost-Effective for Large Parts: Unlike injection molding, which requires expensive tooling for each part, thermoforming uses less complex molds, reducing upfront costs.

-

Flexibility in Design: Thermoforming can produce parts in a wide range of shapes and sizes, from small trays to large enclosures.

-

Rapid Prototyping: The process allows for quick design iterations, making it ideal for industries that need fast turnaround.

-

Material Variety: A wide range of thermoplastics can be used, each offering different strengths, textures, and finishes.

Applications of Thermoforming

Thermoforming is used in many industries because of its adaptability. Common applications include:

-

Packaging: Food containers, clamshells, and blister packs.

-

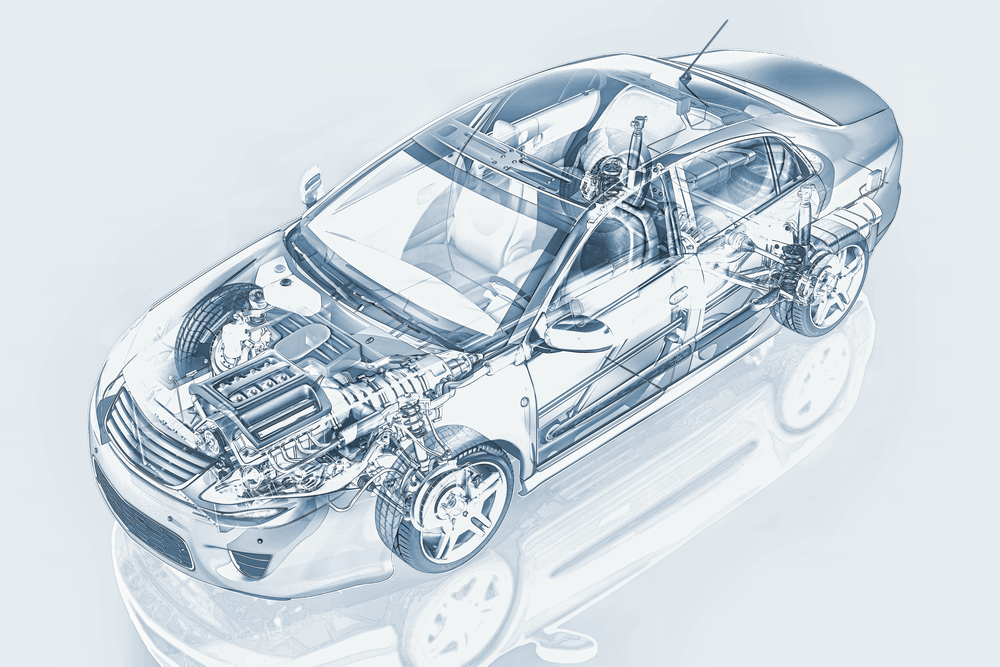

Automotive: Dashboards, door panels, and protective covers.

-

Medical: Sterile trays and equipment housings.

-

Industrial: Equipment enclosures, shipping trays, and protective guards.

Conclusion

Thermoforming is a versatile and efficient manufacturing process that continues to shape the modern world. Its ability to create strong, lightweight, and cost-effective products makes it an invaluable tool for industries ranging from healthcare to automotive. As materials and technology advance, thermoforming is poised to remain a key player in the future of plastic manufacturing.

LinkedIn: https://www.linkedin.com/companyadel-international-north-llc